Injection blow moulding: extra precision

Bottles and jars are only manufactured by injection blow moulding in specific cases. Few manufacturers offer this technique. However, injection blow moulding can be the ideal solution if the neck opening requires a very high level of precision. The injection moulding process is more precise than extrusion blow moulding. This makes the measurements of the neck more precise, resulting in a better seal with the cap. This is important for products which must be kept away from oxygen, such as superglue. The technique is also suitable for the production of deodorant rollers: the space for the roller ball can be made very precisely through the injection moulding process.

In some cases the costs of injection blow moulding are particularly attractive. For example, if you want to manufacture very large numbers of small bottles, the manufacturing costs are relatively low.

Preforming, blowing and cooling

Flestic has three injection blow moulding machines. Injection blow moulding is a two-step process, following directly from one to the next in the same machine. The first step is to make a preform by injection moulding, which is then blown up and cooled down in the second step. Only the body of the preform is blown up. The neck remains unchanged.

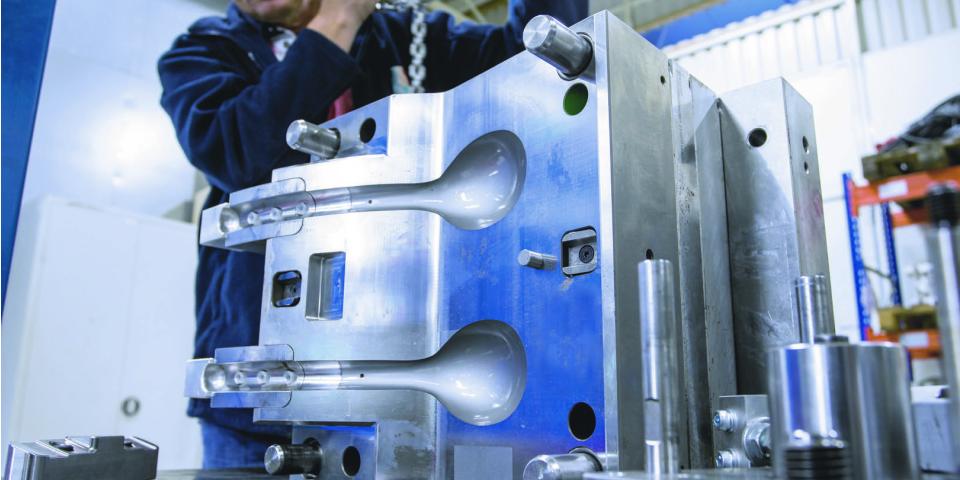

Two moulds are needed for injection blow moulding: a preform mould and a blow mould for blowing up the body of the preform. Development of the injection mould is expensive, because a great deal of research and development is needed to design the preform for a high quality end product.